- Industrial cleaning for virtually all materials.

- Non-toxic and gentle.

- Safe enough for fragile items.

- Strong enough for tough materials.

Welcome to the next evolution of industrial cleaning and remediation! Our blasting techniques clean better than traditional methods like sandblasting or high-pressure water or steam blasting, without leaving residue. With no blasting media to clean up, the process is faster and cheaper than traditional cleaning methods. It is extremely gentle on equipment, machinery and buildings materials, yet tough as nails on grease, mold and other surface contaminates!

PureSpace Offers Superior Industrial Cleaning

- We are one of the only companies in Oregon who offers the dry ice blasting method of cleaning. Industrial cleaning is faster and cheaper with superior results to traditional methods.

- There is virtually no clean up so you can start using your equipment again right away.

- We use the highest quality equipment and materials.

- Equipment can be cleaned in place, without disassembly in most cases.

- Non-conductive, so you don’t even have to turn the equipment off, let alone cool down.

- We go to the highest level to get the maximum results for your money.

- We spend time going over the process with you beforehand so that you know what’s happening every step of the way.

Dry Ice Dusting

Liquid dry ice dusting technology allows us to safely clean more fragile surfaces than standard soda blasting or even our dry ice blasting. It can safely clean electronics, books, drywall and other fragile items. It does not harm these items but still cleans deeply and thoroughly to remove all contaminants, stains, and odors.

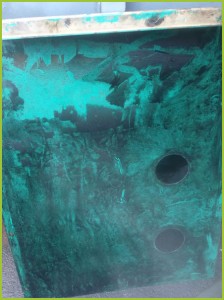

Vapor Blasting

Have a problem too tough for dry ice blasting? Vapor blasting uses water vapor and media to clean really tough surfaces and stains. It cleans as effectively as sand blasting but without damaging materials or leaving residue. We use vapor to hold down the dust while performing very vigorous, aggressive cleaning or paint removal. We can remove toxic, tough materials like lead paint, grease, tar/asphalt and epoxy. This technology is safe, non-toxic and leaves no residue!

Safer, Cleaner, Better

Our cleaning techniques are much safer and easier than traditional blasting techniques. We use non-toxic cleaning materials that leave no residue behind.

- Replaces sand blasting/soda blasting

Sand blasting and bead blasting are highly abrasive, and can damage the material you want to clean. Further, when you are done sand blasting, what do you do with all of that sand or soda? Not only will dry ice not harm the material you want clean, but there is no sand or soda to clean up!

- Replaces steam or water blasting

Dry ice blasting machines are also an improvement over steam and water blasting for several reasons:

- Dry ice is non-conductive, allowing you to put newly cleaned materials immediately back into service, reducing equipment down-time.

- Dry ice blasting does not add any more water to the process, as water is the ‘ignition’ for mold growth. We always work to stop and prevent mold growth.

- Dry ice blasting removes more algae, sea slime, and mussels on boat hulls, than water blasting, which will keep the organic matter from reattaching sooner.

- Replaces environmentally damaging solvents

Commercial dry ice blast cleaning is used in place of environmentally damaging solvents. These toxic chemicals require additional and costly protocols in place. If they leak, they can cause serious damage to groundwater and local environment. Since dry ice evaporates completely as a gas, it leaves no waste. The only items to dispose are any building materials that need to be removed. When commercial dry ice blasting replaces hazardous chemical cleaners, the disposal cost of that chemical is eliminated.

Additional Places Dry Ice Cleaning Has Been Used

Electrical

Electronic/electrical control panels

Cable trays motors/stators

Armatures/coils/windings

Generators

Printed circuit boards

Semi-conductors

Transformers

Switch gear

Robotic equipment

Relays

Turbines

Insulators

Sub-stations

Commercial

Buildings

Exterior/interior

Hospitals/nursing homes

Hotels

Residential

Structures

Heating/cooling systems

Bricks/wood

Remediation/restoration

Graffiti and decal removal

Food

Ovens

Floors

Walls

Processing equipment

Equipment ceilings

Conveyors

Bake-off trays

Packaging areas and equipment

Other

Cigarette/cigar smoke

Formaldehyde

Beauty salons

Waste containers

Nuclear decontamination

Fire restoration

Mold remediation

Health care facilities

Industrial

Molding equipment

Butt welders

Process equipment

Manufacturing equipment

Piping

Tanks

Ship hulls

Automobiles interiors

Printing presses

Pulp/paper equipment

Oil field equipment

Boiler tubes

Aircraft